WATERS 600 MULTISOLVENT DELIVERY SYSTEM CONTROLLER WARRANTY WATCH VIDEO FREESHIP

WATERS 600 MULTISOLVENT DELIVERY SYSTEM CONTROLLER WARRANTY WATCH VIDEO FREESHIP

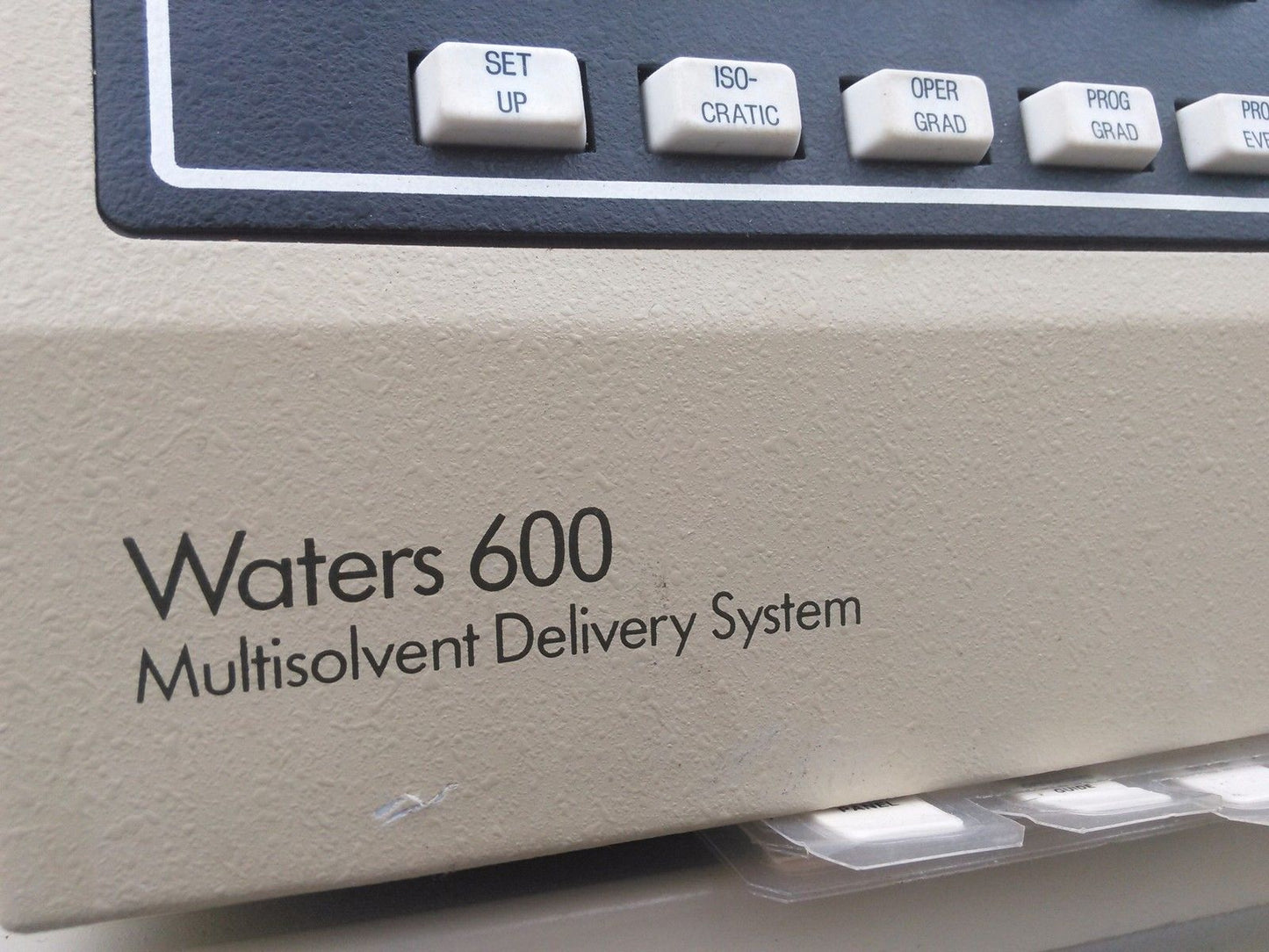

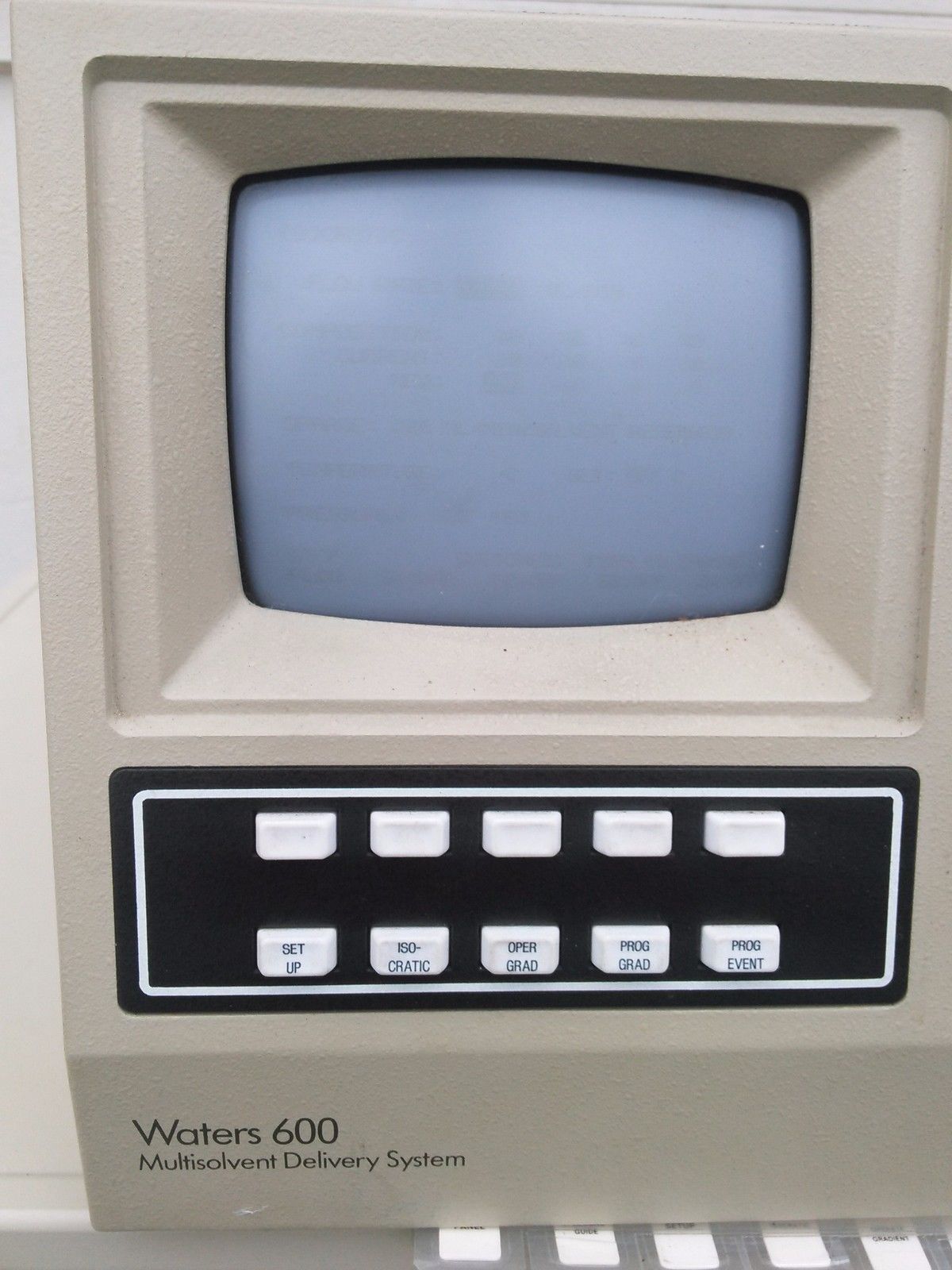

This listing is for a Great Operational condition WATERS 600 MULTISOLVENT DELIVERY SYSTEM CONTROLLER as can be seen in the pictures.

PLEASE FEEL FREE TO WATCH A VIDEO OF THIS UNIT IN OPERATION BY CLICKING https://www.youtube.com/watch?v=YKaCClQH8KY

Please check manufacturer's Specification Technical Data Sheet by clicking https://www.artisantg.com/info/PDF__5761746572735F363030455F4D44535F55736572735F4775696465.pdf

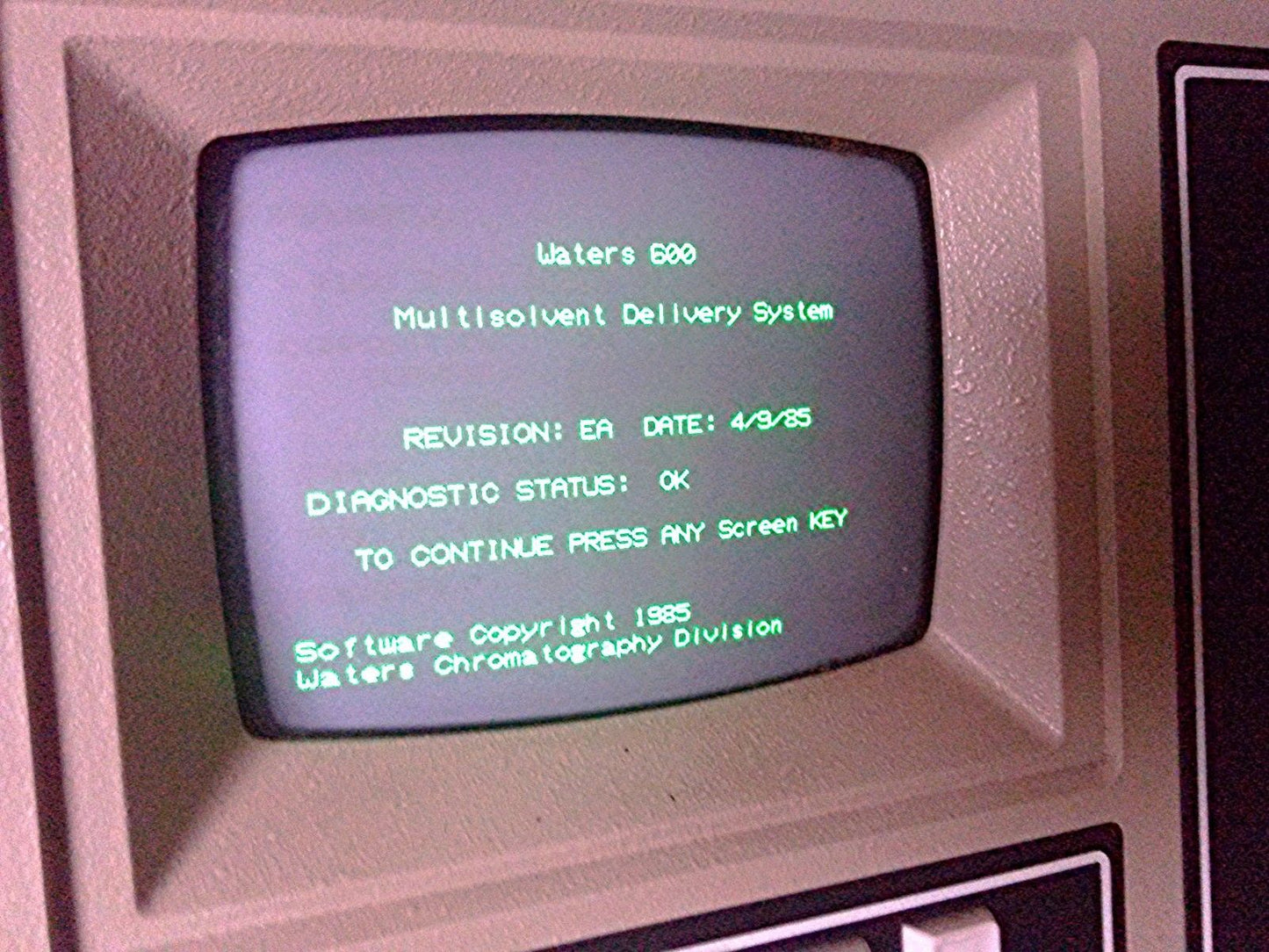

The Waters 600 controller (Figure 1-2) automatically controls the eluent gradient, the flow rate, column heating, external events, and sparging. You can configure the 600 Controller as a PowerLine system controller or as a Gradient controller.

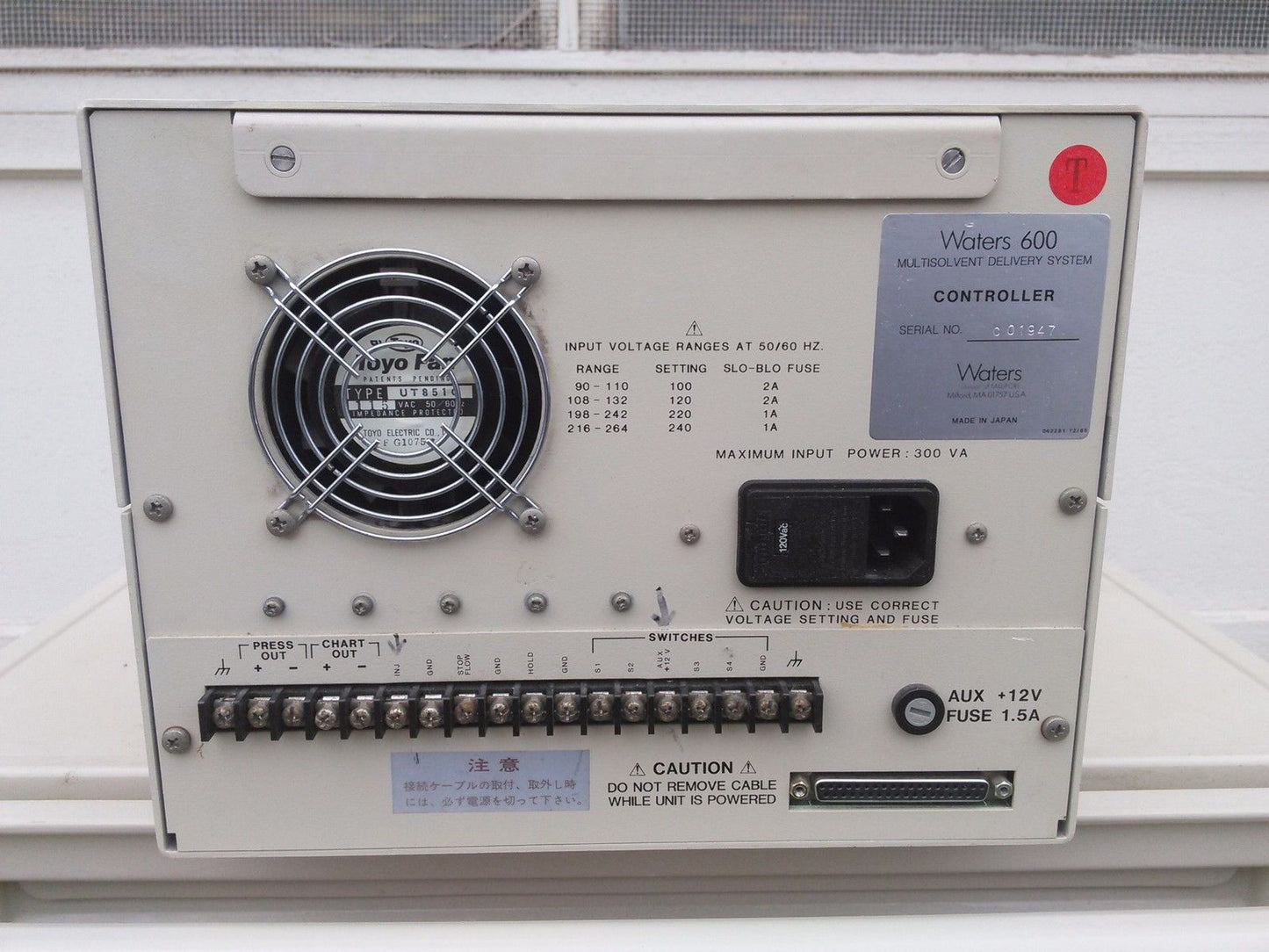

The 600 Controller rear panel (Figure 1-3) provides connection terminals and communication ports for operation with external devices.

Screw Terminals The 600 Controller rear panel contains the following screw terminals: • Pressure • Chart • Inject • Stop Flow • Hold • S1 through S4 (event switches) • Aux +12 V Pressure/Chart Function as output terminals (10 mV full scale analog signals). Located on the controller rear panel. Produce plots of system pressure and percentage of eluent composition, respectively, on any standard recorder or integrator. Inject Accepts the signal from the free-standing manual injector or autosampler to initiate a run. Located on the controller rear panel.

When you configure the 600 controller as a PowerLine system controller, you initiate operation with an autoinjector through: • IEEE-488 communications interface (for use with a PowerLine autoinjector) • Inject terminal (for use with a non-PowerLine autoinjector) When no injector is being used for the separation, and the method start is initiated from the 600 controller front panel using screen keys, the Inject terminal functions as an output. You can connect fraction collectors, integrators, or other devices that require a start signal to the Inject terminal to synchronize operation with the 600 controller. Stop Flow/Hold Both the Stop Flow and the Hold terminals on the controller rear panel are TTL-compatible. • Stop Flow input switch - Allows you to stop the pump unit with a signal from an external device 6 Introduction • Hold output switch - Transmits a signal from the 600 controller to an external device when the controller receives a: – Stop Flow signal – Hold screen key signal – Pressure limit error – Pump flow rate error Event Switches/Aux +12 V Four TTL-compatible connectors (S1 through S4) on the controller rear panel: • Control column-switching valves, fraction collectors, or similar external devices • Operate manually or automatically through the 600 controller screens • Function in conjunction with a built-in auxiliary power supply terminal (Aux +12 V) for devices that require an external power source.

Couldn't load pickup availability

Low stock: 1 left

View full details