90DAY-WARRANTY GATAN MODEL 656 MK 3 DIMPLE GRINDER FREE-SHIP

90DAY-WARRANTY GATAN MODEL 656 MK 3 DIMPLE GRINDER FREE-SHIP

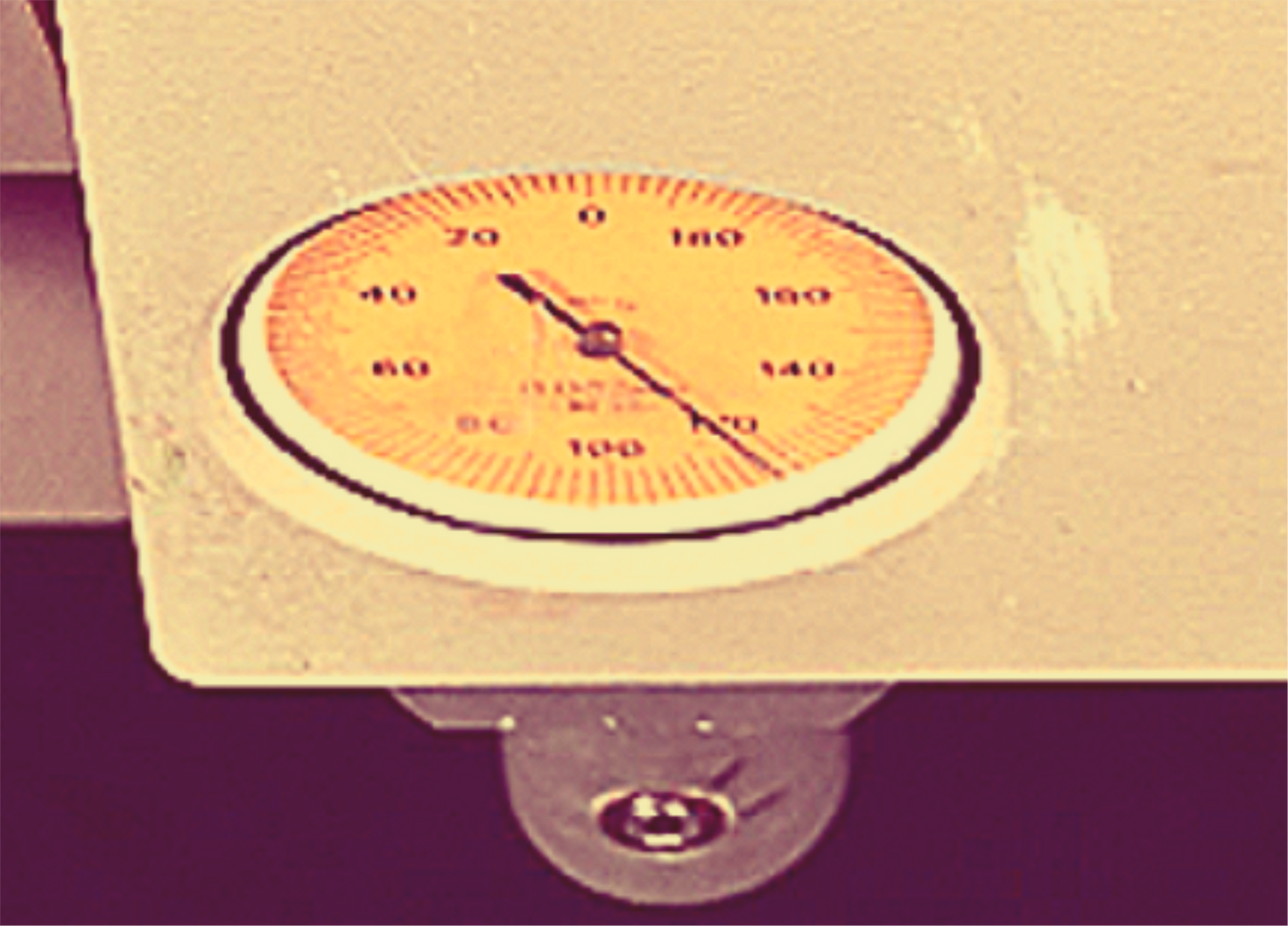

This listing is for a Wonderful Operational Pre-owned Condition GATAN MODEL 656 MK 3 DIMPLE GRINDER as can be seen in the pictures.

Gatan Model 656 Mk 3 Dimple Grinder (for TEM) Power Cable Included

Qty:1G

Manufacturer: Gatan

Model: Model 656 Mk 3

Type: Dimple Grinder (for TEM)

Power: Power Cable Included

Condition: Has been Fully Tested.

IMPORTANT: The unit came from a Federal University and has ALWAYS been very well taken care of as can be seen in the pictures.

This GATAN MODEL 656 MK 3 DIMPLE GRINDER has been fully tested and is GUARANTEED to perform at factory specifications and that's why we offer a 90-DAY-WARRANTY on this unit!!!

Technical Information below in BLUE ITALICS was taken online from Manufacturer's website:

tem-analysis.com/instruction-manuals/gatan-656-dimple-grinder-instruction-manual.pdf

1.0 Overview The Gatan Model 656 Dimple Grinder is a precision instrument used to produce circular dimples (spherical or flat-bottomed profile) in materials such as ceramics, semiconductors, metals, and combinations thereof. The principle application is in the preparation of TEM specimens. When specimens are mechanically dimpled prior to final thinning, the finished specimen has a more uniform thickness, has a larger than usual electron-transparent area, and is very robust with a thick rim surrounding the central thin region. In the case of neutral-particle beam-thinning systems, the time required for final thinning is significantly reduced with dimpling. With most metals, a 20-µm specimen can be obtained by dimpling and the mechanical damage introduced into the specimen surface by the grinding action is removed with additional final thinning by electro polishing, ion-beam thinning, etc. A final specimen thickness of <5 µm can routinely be produced by a careful operator. The Dimple Grinder is gentle enough and provides sufficient control over the process of dimpling that many materials, such as ceramics and semiconductors, can be thinned below 3 µm with practically no mechanical damage and viewed subsequently in intermediate- and high-voltage TEMs without further thinning. Additionally, the electron-transparent area may be precisely positioned in the specimen, laterally to within a few tens of microns and vertically to within a few microns– not always possible with other dimpling instruments. Other applications of the Dimple Grinder include the production of accurate, precisely-located taper sections through the surface of specimens, which may then be subjected to analytical techniques such as EDX, SIMS, Auger, etc. In this way, compositional profiles of segregated surface layers, coatings, and platings can be obtained rapidly and with excellent “depth resolution.”

All of our equipment is fully tested to perform at factory specifications before being shipped.

The picture is the actual item buyer will receive.

FREE USA SHIPPING ALSO!!!

INTERNATIONAL BUYERS PLS CONTACT US FOR A SHIPPING QUOTE!!!

Stock # 242109

Couldn't load pickup availability

Out of stock

View full details